Colorado OSHA Compliant Guide to Forklift Certification

In Colorado’s busy work areas, keeping safe while using forklifts is really important. OSHA National Safety Training provides a detailed forklift training program that fits the needs of workers all across Colorado. This program follows the strict rules of OSHA and is made to handle the different challenges that come with using forklifts in various kinds of jobs in Colorado.

Our training covers everything from the basics of using a forklift to the more complex parts of handling them in different work settings. Whether it’s moving things in a crowded warehouse, working in a factory, or using a forklift outside on a construction site, our program teaches how to do it safely and well.

But it’s not just about following the law. Our program is about making sure everyone stays safe. We teach how to check the forklift to make sure it’s safe to use and how to understand what a forklift can and can’t do. This helps prevent accidents at work and makes the workplace better and more productive.

In short, OSHA National Safety Training’s forklift program in Colorado is more than just learning how to use a forklift. It’s a full plan to make sure forklift use is safe and effective in all kinds of jobs across the state.

For organizations employing forklift operators in Colorado, obtaining forklift certification is not just a crucial component of your safety protocols – it’s a legal requirement. Before your operators can commence work, ensuring they are certified is essential for both compliance and maintaining a safe working environment.

Training Options for Forklift Certification in Colorado

Our online forklift operator certification in Colorado is not only highly affordable at just $49.00, but it’s also a valuable investment in ensuring workplace safety and meeting OSHA standards. Additionally, we provide onsite training services at the most competitive rates in Colorado, offering both cost-effectiveness and quality training solutions. Check out our onsite forklift safety training courses for businesses.

Warehouse Forklifts – Class 1, 4 and 5 Powered Industrial Trucks

- Class 1: Electric Motor Rider Trucks

- Class 4: Internal Combustion Engine Trucks – Cushion (Solid) Tires

- Class 5: Internal Combustion Engine Trucks – Pneumatic Tires

Forklift Certification in Colorado – Pallet Jacks & Order Pickers – Class 2 & 3 Lifts

- Class 2: Electric Motor Narrow Aisle Trucks

- Class 3: Electric Motor Hand or Hand/Rider Trucks

Colorado Forklift Certification for Construction & Heavy Duty Work – Rough Terrain Forklifts

- Class 7: Rough Terrain and Construction Lifts – Telescopic Lifts

Get Certified Today!

The Value of 3rd Party On Site Forklift Safety Training in Colorado:

Forklift Types

- Class 1 – Electric Forklift

- Class 2 – Electric Narrow Aisle Trucks

- Class 3 – Motor Pallet Jacks

- Class 4 – Combustion Engine Forklifts (Cushion Tire)

- Class 5 – Rough Terrain Forklifts (Pneumatic Tires)

- Class 6 – Electric and Combustion Tractors

- Class 7 – Rough Terrain Forklifts

One Day Onsite Forklift Training Agenda

Duration: Between 4-6 hours depending on type of training.

Session 1: Getting to Know Forklifts and Staying Safe

In this first session, everyone learns about forklifts and how to be safe around them. We start with a friendly welcome and get to know each other, making sure everyone feels good about learning. We talk about what we’ll learn in the training, focusing on the main points and goals. We stress how important training is right at the workplace to keep everyone safe and avoid accidents. We remind everyone that they play a big part in making their workplace safer and ask them to join in the training with enthusiasm. This session prepares everyone for a learning journey focused on safety.

Session 2: Different Forklifts and Their Parts

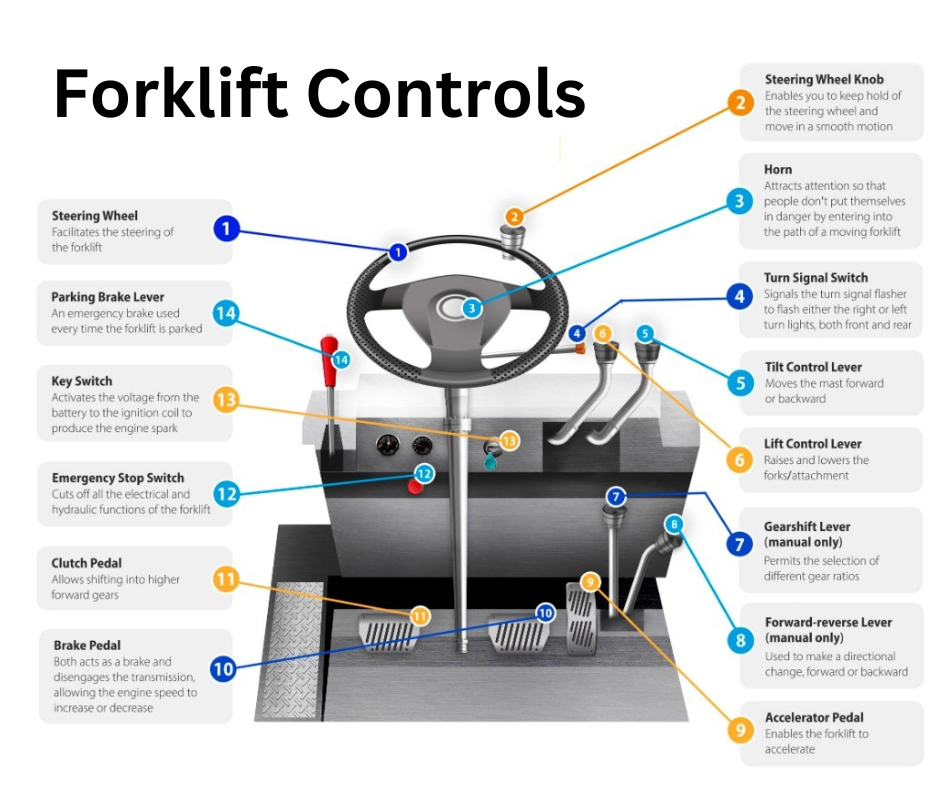

Here, we explore different kinds of forklifts and what they’re used for. Participants learn about the seven main types, like counterbalance forklifts, reach trucks, and pallet jacks, and how they’re used in various industries. We also look closely at the parts of a forklift and how to control them. We put a lot of focus on using these controls safely and correctly to work efficiently and safely. This session gives everyone the knowledge to choose and use the right forklift for their tasks, making the workplace safer and more productive.

kinds of forklifts and what they’re used for. Participants learn about the seven main types, like counterbalance forklifts, reach trucks, and pallet jacks, and how they’re used in various industries. We also look closely at the parts of a forklift and how to control them. We put a lot of focus on using these controls safely and correctly to work efficiently and safely. This session gives everyone the knowledge to choose and use the right forklift for their tasks, making the workplace safer and more productive.

Session 3: Checking Forklifts Before Use and Understanding Stability

We learn how important it is to check forklifts before using them and to understand how stable they are. These checks are key to making sure the forklift is safe and works well, which helps prevent accidents and expensive repairs. Operators check many parts like tires, fluids, forks, controls, lights, and brakes for any damage or problems. We talk about how to mark a forklift as “out of service” if it’s not safe to use and how it shouldn’t be used until fixed by someone who’s allowed to. This session highlights the need to always be safe and follow rules to keep forklift operations safe and efficient.

Session 4: Learning to Drive a Forklift

This session is all about actually driving a forklift in a safe area. We focus on teaching everyone how to drive and control a forklift safely and well. Participants practice steering and driving carefully, especially in tight spaces or on difficult ground. They also learn basic skills for handling loads, like picking up, placing, and stacking things. This session gives everyone the practical skills they need to drive a forklift safely, preparing them for real situations at work.

Session 5: Knowing and Handling Forklift Dangers

We dive into understanding and dealing with dangers when using forklifts. The session starts by teaching how to spot possible dangers at work, making everyone more aware of their surroundings. We talk a lot about how to avoid common forklift accidents, sharing tips on preventing risks.

We dive into understanding and dealing with dangers when using forklifts. The session starts by teaching how to spot possible dangers at work, making everyone more aware of their surroundings. We talk a lot about how to avoid common forklift accidents, sharing tips on preventing risks.

There’s also a practical test where everyone gets to use their forklift skills in real situations. This test is important to see how well they can use a forklift safely and effectively. By looking at how they do, participants learn what they’re good at and what they need to work on, helping them be safer and better at using forklifts at work.

Session 6: Getting Your Forklift Certificate and Wrapping Up

In the final session, those who do well get certificates to show they know how to use forklifts safely and well.

We also go over the main points and safety tips from the training again. This helps make sure everyone remembers what they’ve learned about forklift safety and use.

We end with a chance for questions and feedback, letting everyone ask about anything they’re still unsure about and share their thoughts and experiences. This part is great for talking openly and sharing helpful feedback, which helps make forklift use and future training even better. Session 6 wraps up the training nicely, leaving everyone ready to help make their workplace safer and more skilled at using forklifts.